Guided Project SS26_11 »Structured Robotic Assembly of Modular Objects«

Organizational Details

- Supervisor(s)

- Nicolas Pyschny, Yuvesh C. Aubeeluck

- Team size

- 3-5

- Language

- English

- Start

- End March

- Offered as

- GP-TS-ACS (12+6 ECTS)

Robotic assembly of modular objects remains a central challenge in automation, particularly when physical interactions such as contact forces, insertion tolerances, and alignment errors play a decisive role. While industrial solutions often rely on highly specialized fixtures or pre-tuned procedures, such approaches are inflexible and difficult to generalize to new assembly tasks or object configurations.

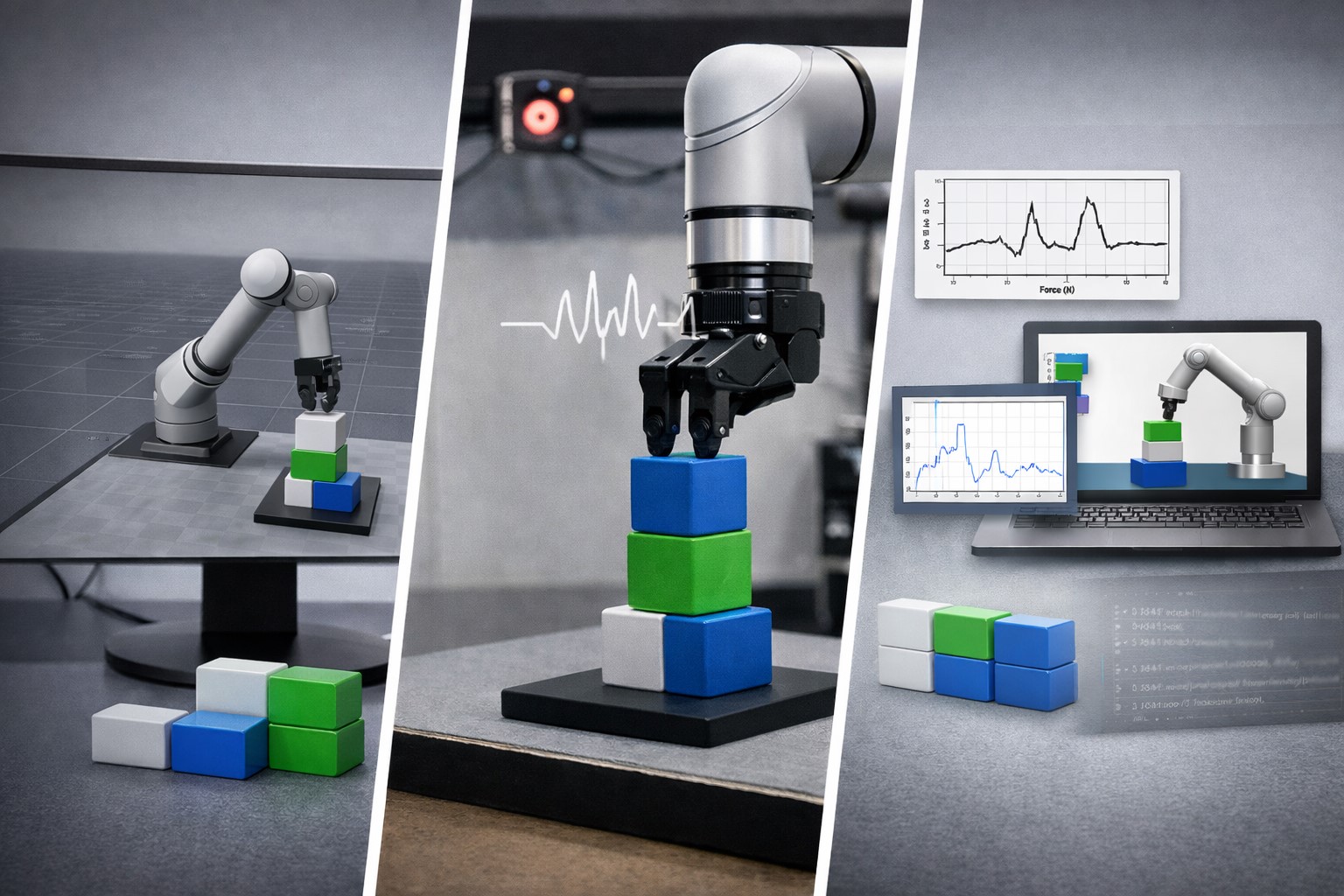

This project is motivated by the need for structured, programmable assembly strategies that explicitly account for object order, geometry, and interaction mechanics, rather than relying solely on end-to-end learning or black-box AI approaches, but a hybrid combination of AI-based and classical methods. Using simple yet representative objects (e.g., LEGO-like bricks), the project explores how robots can be instructed to assemble predefined object stacks in a robust and adaptable way, combining simulation, physical modeling, and algorithmic planning.

The goal of this guided project is to design, implement, and evaluate structured robotic assembly methodologies for stacking and assembling modular objects using a 6-axis robotic arm. Students will work in small teams to define an experimental setup, select objects to assemble, and develop multiple assembly strategies that respect a predefined assembly order (e.g., order of stacking).

The project emphasizes a methodological approach rather than a single fixed solution. Students will design and compare different strategies for picking, aligning, inserting, and stacking objects, considering factors such as contact forces, insertion difficulty, compliance, and positional uncertainty. These strategies will be implemented and tested primarily in a simulation environment (Isaac Sim), with optional transfer to a real robotic system (Universal Robots) where feasible.

Key activities include:

Deliverables include documented assembly strategies, implemented control code, experimental results, and a final presentation demonstrating the effectiveness and limitations of the proposed approaches.

After completing the project, students will:

Critically assess when learning-based methods are useful; and when analytical or rule-based methods are preferable.

Prior experience with machine learning is not required, but students should be open to evaluating learning-from-demonstration methods as one possible tool among others.

Innovation Hub Bergisches RheinLand